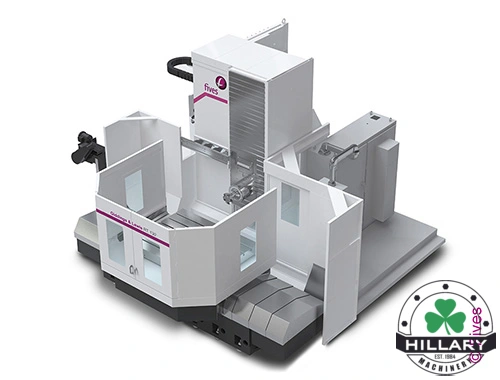

Giddings & Lewis T-Bed HBMs - a Job Shop Workhorse

For maximum productivity at a minimal cost, the Giddings & Lewis T-bed horizontal boring mill is hard to beat. Fives has a tradition of building rigid, accurate and reliable machine tools. The Giddings & Lewis T-bed HBM carries on that tradition but at a price level that will appeal to every shop.

— 78.74" X-AXIS TRAVEL (OPTIONAL 118.11")

— 59" Y-AXIS TRAVEL (OPTIONAL 78.74")

— 47.2" x 55.1" TABLE (OPTIONAL 55.11" X 70.86")

Giddings & Lewis T-bed HBM advantages

Rigid machining platform for heavy precision cutting

o Cast iron construction

o Cross-braced column

o Hydrostatic table with 360 degree table clamping for added rigidity

o Dual servo B-axis table, electronically compensated for zero backlash

-Flat floor installation reduces foundation and installation costs

-Economical chip management

-Integral coolant pan for chip and coolant containment

-Electronically-counterbalanced headstock provides superior contouring performance

— 78.74" X-AXIS TRAVEL (OPTIONAL 118.11")

— 59" Y-AXIS TRAVEL (OPTIONAL 78.74")

— 47.2" x 55.1" TABLE (OPTIONAL 55.11" X 70.86")

— Full contouring 360,000 position table

— 10 ton (22,000 lb) capacity

— 130 mm (5.1 inch) spindle

— 22 kW (30 hp) continuous power

— Coolant through-spindle

— 40 tool magazine

— 35 kg (77 lb) max tool weight

— 600 mm (23.6 in) max tool length

— Table enclosure as shown

— Part probe

— Flat-floor installation, no pit required

— Industry-leading G&L accuracy, rigidity and performance

We use cookies to improve your experience. Privacy Policy.