New

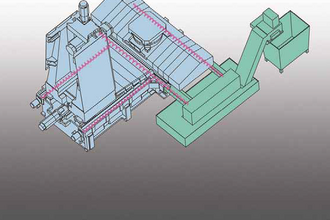

Niigata HN50E Heavy Duty Box Way Geared Head Horizontal Machining Center

Horizontal Machining Centers

Heavy duty boxway machining center features solid meehanite cast iron machine frame. Outstanding stability, damping through extensive ribbing of machine frame. Wide induction hardened boxways for long-term accuracy and rigidity. All axes hand scrapped by highly experienced technicians. Gear driven spindles that general extremely high torque. Niigata’s mean workzone is the most generous in the industry.

| Taper | CAT50 (BIG PLUS) |

| X Travel | 31.5" |

| Y Travel | 27.6" |

| Pallet-W | 19.7" |

| Pallet-L | 19.7" |

| Z Travel | 22.8" |

| RPM | 6,000 RPM |

| Control | CNC (Fanuc) |