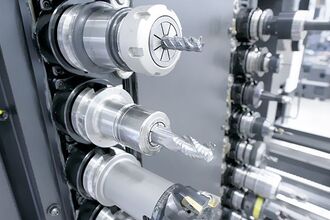

Hyundai-Wia HS4000i 400mm 12K RPM High Speed Dual Pallet Horizontal Machining Center

Horizontal Machining Centers

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

The HS4000i is manufactured using the latest state-of the-art manufacturing technology and is one of the most versatile members of HYUNDAI-WIA’s outstanding line of CNC Horizontal Machining Centers. The HS series has been designed to meet the demanding requirements found in today metal working market.

PDF http://hillaryinc.net/hwpdf/HillaryMachinery-HyundaiWia-HS%20Series.pdf

Customer Reviews https://hillarymachinery.com/hyundai-wia-cnc-reviews

• Fanuc 32i-B Control

• 12,000 RPM built-in spindle

• Powerful 25kW (34 HP) spindle motor

• High precision spindle with double row angular contact ball bearings

• BCV # 40 Spindle Taper

• 1 Degree Table (Optional 0.001 degree)

• Oil jacket spindle cooler

• 1,000 PSI through the spindle coolant

• Massive Meehanite cast iron bed

• Large Linear Roller Guide Ways

• Table clamping by large diameter Curvic coupling

• Fast 60m/min (1.968 IPM) X,Y and Z rapid traverse

• Rigid tapping

• Custom Macro (User Definable)

• Servo Driven Double Arm ATC 60 Tools

• Automatic pallet changer with (2) Tapped pallets

• Qualified edge locators

• Pallet clamping by 4-cone type pins

• Pallet rotation at pallet loading station

• Portable Manual Pulse Generator

• Program and data protection key switch

• Telescopic way covers

• Full enclosure splash guard

• Dual screw type conveyors

• Chip Conveyor (47” discharge height)

• Flood coolant with large separate coolant tank

• Work light

• 3 color tower signal light

• Instruction manual, parts list, and electrical drawings

• Fanuc operator and maintenance manuals

• Two-year machine warranty: Parts and 1 Year Labor

• Two-year control and motor warranty: Parts and Labor

| Taper | CAT40 (BIG PLUS) |

| X Travel | 24.4" |

| Y Travel | 22" |

| Pallet-W | 15.8" |

| Pallet-L | 15.8" |

| Z Travel | 25.6" |

| Power | 34 hp |

| RPM | 12,000 RPM |

| Control | CNC (Fanuc) |