New

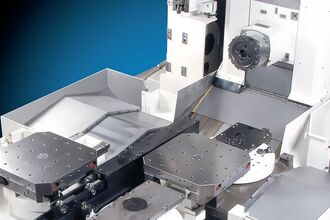

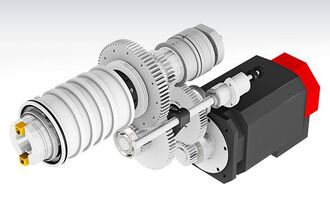

Hyundai-Wia KH63G 630mm Heavy Duty Dual Pallet Box Way Geared Head Horizontal Machining Center

Horizontal Machining Centers

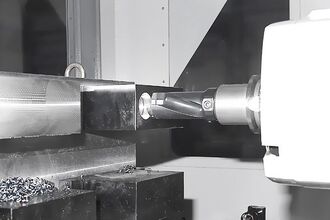

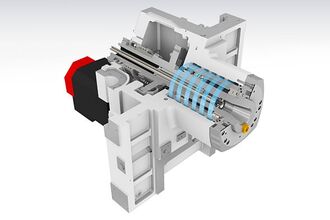

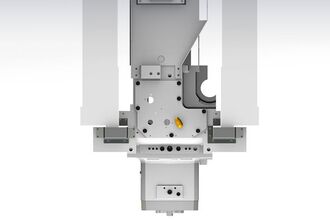

The KH63G is manufactured using the latest state-of the-art manufacturing technology and is one of the most versatile members of HYUNDAI-WIA’s outstanding line of CNC Horizontal Machining Centers. The KH63G has been designed to meet the demanding requirements found in today metal working market.

PDF http://hillaryinc.net/hwpdf/HillaryMachinery-HyundaiWia-KH50G-63G.pdf

Customer Reviews https://hillarymachinery.com/hyundai-wia-cnc-reviews

| Taper | CAT50 (BIG PLUS) |

| X Travel | 37.4" |

| Y Travel | 32.5" |

| Pallet-W | 24.8" |

| Pallet-L | 24.8" |

| Z Travel | 29.9" |

| Power | 35 hp |

| RPM | 8,000 RPM |

| Control | CNC (Fanuc) |